Fun fact: Torx screwdrivers are compatible with Torx Plus screws, but Trox Plus screwdrivers are only compatible with Torx screws that are one size larger

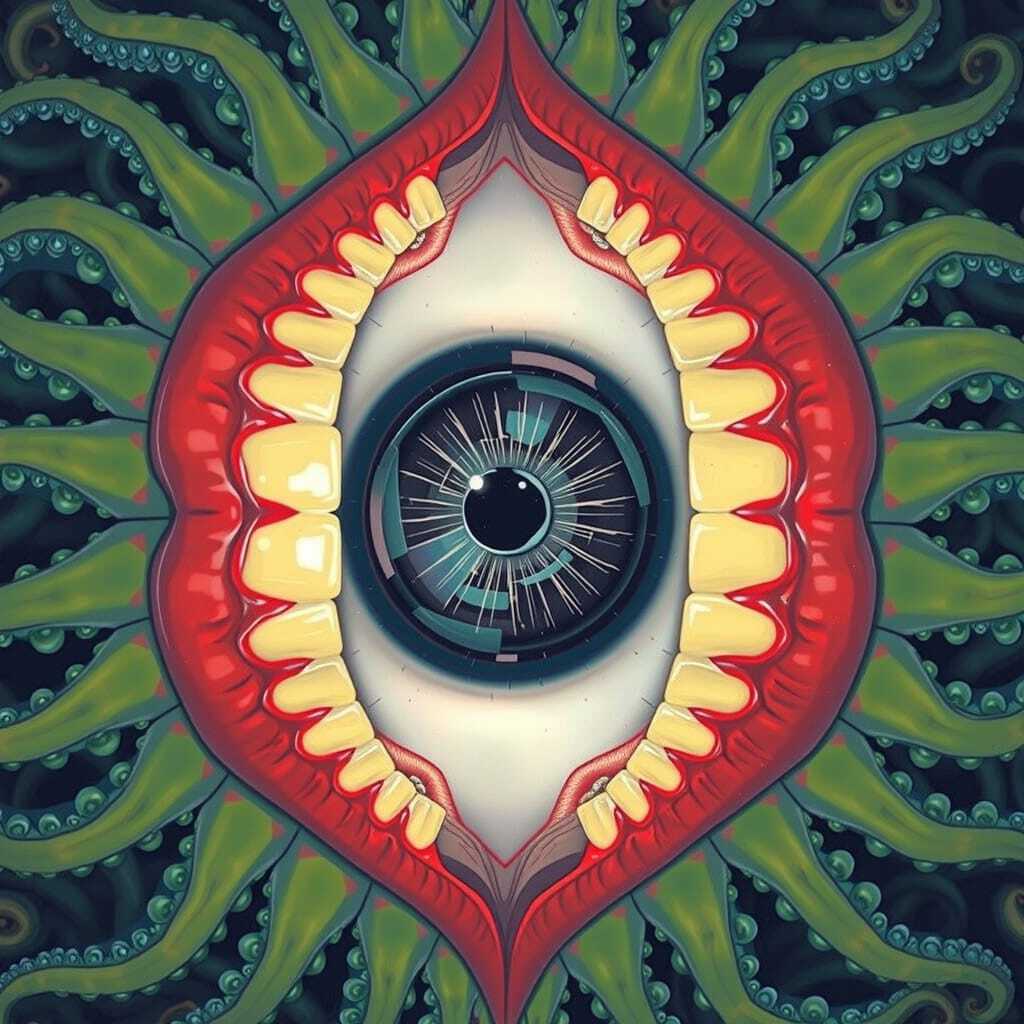

Why does Torx Plus have six teeth but tamper-resistant Torx Plus has five? Whereas ‘what the fuck is this’ basically looks like it should be tamper-resistant Torx Plus?

I guess they wanted to make the screws even more tamper-resistant? With the standard Torx Tamper-Resistant screws, they could often be bypassed by chiseling the pin away with a flathead and a hammer, and then using a standard Torx driver. Can’t do that with the pentalobular design!

Y’all need Jesus

^H^H^H^H^H^HRobertson screws.___Ah, torx plus, used on Chevy bellhousings. Real easy to strip with a regular torx driver.

Also great for tamper-resistant screws. Makes it harder for my patients to get screws out to make weapons / self injury implements or to get to the electrical wiring or create a ligature attachment point.

Why is tamper-resistant torx plus the only one that’s 5-pronged?

because the goal of tamper resistance is to make it harder to unscrew without apple’s approval

To make it even less likely that someone will be able to get it unscrewed without having the right set.

They’re not perfect, obviously, but they do harden a target more than regular Torx.

I use tamper resistant screws to keep an AirTag on my eBike to discourage its removal. Obviously a determined thief could remove it, but lots of stolen bikes get abandoned anyway. My hope is that if it gets stolen it gets abandoned and I can find it then.

Apple?

Reject threaded fasteners, return to nail and rivet.

We can debate this all day long but we all know torque is cheap.

But enough torque, have at thee!

my brother in christ have you seen phillips head and posi drive?

Life sucks. You can’t win.

Or Phillips and JIS?

Working on an 86 RV and hating posi drive. I swear they were designed to strip.

Also no mention of Spider drive that everyone insists is a torx

+1 for hex, but that’s in a lab setting — climate controlled environment, generally not high torque, pretty benign conditions. But even that is fraught with metric-vs.-imperial mix ups.

The key is to drag the US into the future along with literally everyone but Liberia and Myanmar.

But even that is fraught with metric-vs.-imperial mix ups.

Get a set of rotary broaches in the nearest metric size up from the imperial ones and remove the problem.

Lmao you’ve clearly never met Philips.

And if you’re advocating slotted screws (flathead) you’ve already lost.

Torx is supreme. The end.

Robertson is superior.

Hex is supreme, torx is mental health problem

deleted by creator

No slot shaming!

the worst is not when the screwdriver is fucked but the screw is. That is some huge pain in the ass

Torx doesn’t get fucked though, compared to alan or philips

What about square drive… where does it fit in

Removed by mod

Robertson! Say his name!

I was saying it in Mercian for our southern neighbours

I’m not american so you wasted it anyways

That’s right, it goes in the square hole.

Fun fact: There are plenty of times a screw that looks like a Philips head is also compatible with a square drive. I’ve mostly seen this on electrical outlets and Ikea furniture.

I don’t know why Robertson/square drives aren’t more common. They’re stable and they resist stripping and rounding.

wait really? I would imagine those small corners would easily get flattened compared to something with deeper ridges like philips

Phillips strips way, way easier than Torx. Stripping generally happens when a screwdriver cams out, or pops out of the screw. Here are some excerpts from Wikipedia of Torx vs Phillips.

The hexalobular socket screw drive, often referred to by the original proprietary brand name Torx ( /ˈtɔːrks/) or by the alternative generic name star drive, uses a star-shaped recess in the fastener with six rounded points. It was designed to permit increased torque transfer from the driver to the bit compared to other drive systems. The drive was developed in 1967[44] by Camcar Textron.[45] Torx is very popular in the automotive and electronics industries because of resistance to cam out, and extended bit life, as well as reduced operator fatigue by minimizing the need to bear down on the drive tool to prevent cam out.

And Philips on the other hand:

The Phillips screwdriver design has a tendency to cam out during operation due to angled contact surfaces which create an axial force pushing the driver out of the recess as torque is applied. Despite popular belief,[2] there is no clear evidence that this was a deliberate design feature. When the original patent application was filed in 1933, the inventors described the key objectives as providing a screw head recess that (a) may be produced by a simple punching operation and which (b) is adapted for firm engagement with a driving tool with “no tendency of the driver to cam out”.

I’m not sure about Allen. It doesn’t cam out very much, but it does still strip a lot easier than Torx. Probably due to the smaller contact points.

Well said.

And with the hex/Allen, it’s the small contact points as well as the smaller volume of material that needs to be deformed or removed before slippage can occur, as well as the angle of force on the contact point.

With a hex, the contact point and direction are such that the tool is effectively trying to scrape off material at an angle, and if/when it succeeds even a little bit, it’s now much more prone to fail.

With a Torx, the contact area might still be small, but it’s being applied to the lobe in a more perpendicular direction, so rather than a scraping failure, it’s more of a force that is pushing directly against steel instead of scraping. Not that it can’t fail, but the route to failure is significantly less likely.

Maybe because different material? Obviously CrV steel won’t get fucked like chinesium, no matter the shape.

Useful tip: with security torx screws, with the little nub in the centre, if you get a small flathead screwdriver to jam in there and wiggle a bit, that centre bit will snap off without much difficulty.

You should be able to use a regular Torx screwdriver bit after that.It’s easier to just pick up security bits at any hardware store…

deleted by creator

This is really gonna come in handy during some of my heists

Their only “heists” when you get caught, until then they’re “shenanigans” 😁

I’m Jewish, so I’m going to have to go with the tamper-resistant Torx when I need to use screws on myself.

Edit: A troll flagged this as antisemitic, so apparently I hate my own ethnicity?

Welcome to the internet

Would you mind explaining? I think not being Jewish and not having enough he-bros is making this go over my head.

It’s a Star of David.

Oh my… Now I feel silly. I was trying to find wordplay and not looking at the image because I’m familiar with Torx variants.